Unveiling the Superior Sport Cage Design from Kincer Chassis in Knoxville

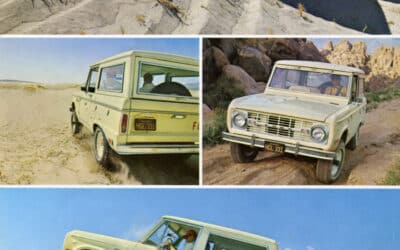

I’ve already picked up the Classic Bronco sport cage from Kincer Chassis in Knoxville, Tennessee, and I’m going to give a quick tour of that facility. It’s amazing up there. Those guys are kind of flying under the radar, but they’re killing it and doing some really amazing work. It seems that only people in the Bronco and F100 world know about them, but you should check it out.

Revolutionizing Bronco and F100 Upgrades: A Tour Through Kincer Chassis Facility

Once at the shop, Thomas visits the sports cage production jig which makes sure all our sport cages fit perfectly inside your Bronco. Here he talks to Kyleigh about the jig.

Inside the inner body panels, right along the edges of the floor—amazing. This jig is basically set up to ensure that the sport cage fits in each and every vintage Bronco. The cool thing of these roll bars is that unlike most classic Broncos, which had a tube extending to the floor on either the passenger side footwell or driver side footwell—requiring a repositioning of the glove box, these roll bars bolt into the upper windshield frame, retaining the functionality of the vent windows. This feature enhances the vintage feel of the truck while providing a cool breeze as you drive.

The large number of classic Broncos here not only highlights how many are on the road but also how many are about to hit the road. The sport cage setup is brilliant with bungs welded for seat belt bolts on both driver and passenger sides. I opted for this cage specifically because it’s a family-style cage, extending to the back of the truck and providing rear seat passenger shoulder harnesses. This means I can finally replace the car seats that my kids have been using for years. This product is a superior upgrade.

Unlocking the Potential of Godzilla Setup in F100 Conversion

Thomas moves on to our old Ford truck section of our shop and talks with Austin, our Lead Engineer at Kincer Chasss.

Now, regarding this F100 conversion, it’s impressive with a Godzilla setup. We assembled this to figure out the conversion from a 2-wheel drive frame to a 4-wheel drive. Over the years, forums have suggested simply getting a 4-wheel drive frame, but we believed there was another way. So, we scanned all the classic frames, positioned our engines accordingly, and built around that. This specific one ended up with a 7.3, though it could have had a 5.0.

The axle was assembled in-house, compatible with either five-lug outers similar to your 150 stuff or eight-lug outers. We’re currently developing a similar kit for Super Duty axles. The frame components will remain largely the same with some different coil buckets and radius arms for bolting up the Super Duty setup. Essentially, everything in orange constitutes your conversion kit.

In the two-wheel drive setup, there’s a huge stamped piece serving as the crossmember. You just cut it out, drill out the rivets for the coil buckets, and remove them—similar to what you’d do for a Crown Vic, except this stuff tucks inside the frame rail. Regarding what welds on, it’s actua lly just these two boxes on the inside of the frame. You insert those, firm them out, and use spacers to get your spacing right. Some drilling through the frame is required for your steering box.

The stock two-wheel drive steering box is positioned at the back, but we placed it at the front using 78, 79 four-wheel drive steering boxes which are robust. We plan to use the same setup on Super Duty, keeping it away from your 7.3 and all your front accessory drives. This design is compatible with any of the stock drive frames as well as 7.3 or 5.0 Coyote configurations (we also install Coyote engines in Classic Broncos). Given the rising prices on Hi Boys, this conversion makes a lot of sense for those desiring functionality on F100s—it will result in a great truck.

The Godzilla setup is absurd, fitting the entire Super Duty drivetrain including Super Duty transmission and transfer case. The transmission here is a 6R140, though a 10R140 could have been used as they have similar external packaging. It employs electronically shifted Super Duty transfer cases with custom adapters designed for standard drive shafts. Currently, we’re ensuring everything fits as intended, developing a kit for front coilovers, and checking some transmission funnels on the 372 trucks with varying heights.

The manual transmissions have different transmission tunnels compared to the automatic transmissions. We’ll also be examining the rears, considering different leaf spring mounts as there are numerous widths of leaf springs. Initially, we’ll make it work with stock Super Duty axles for a streamlined conversion.

Tesla-Powered Electric Bronco: A Glimpse into the Future of Eco-Friendly Off-Roading

The decking used in this Electric EV Bronco resembles yacht decking, a material used on sailboats to replace teak decking. It’s an impressive choice due to its waterproof nature and aesthetic similarity to teak decking, while essentially being a rubber mat. If scuffed, it can be sanded just like wood to re-add the grain—a product called Permateek. The incorporation of a standard charger, not a Tesla charger, is a brilliant addition for car enthusiasts. This electric Bronco design is superior, featuring a party frunk for gearing up, particularly appealing as this truck is Hawaii-bound.

Interestingly, it’s powered by Tesla batteries from a 2016 Model S, with an 85 kilowatt-hour capacity, but the motor is assembled by a company called Stealth EV. It’s a Borg Warner cartridge connected to a little gear reduction unit, leading down to a standard Atlas transfer case.

Beyond the transfer case, it’s a normal Bronco setup with a Builder Series frame. This lightweight truck with an electric motor is perfect for environments with good charging infrastructure, especially for short trips like beach outings.

This setup is ideal, unless you’re into overlanding or covering long distances—then keeping the V8 or opting for a Godzilla setup is advisable. It’s all valid. The engineering is remarkable and is highly appreciated.

The project was undertaken to explore the feasibility of putting an electric chassis into production. The learning experience revealed that it’s not the direction we wish to take.

Thomas says, although a few people are doing it and promoting it, until it’s seen on the road driving, it doesn’t exist. It’s one thing to build one, but a whole different challenge to build 10 or 100.

Custom Chassis Selection: Classic, Coil Sprung, and Coil Over Custom Options

There are three different chassis styles available: the classic style with stock-style radius arms and rear leaf springs, a coil-sprung version for hardcore rock crawling, and a coil-over custom 4-WD setup. Each style has its own unique features, like the single-shock rear mount in the classic style, which is adequate with a good shock. For hardcore off-roading and fun, the coil-sprung version is the way to go. The coil-over setup with custom gear sets and large tires (37 to 40 inches) is perfect for high-speed off-road driving, with 6-piston Wilwoods up front ensuring effective stopping power for the rolling weight.

A black-light is used for each point of inspection on the chassis, ensuring everything is torqued properly with a red mark, followed by a blue mark once set.

Family-Friendly Bronco Sport Cage Installations

Lastly, the cage has welded setups for rear shoulder harnesses, requiring bolting through the floor with possibly some extra steel plates on the bottom for reinforcement. Before installing this frame into the Classic Bronco, it’s important to place the removable steel hardtop on to allow the front window frame to settle, ensuring proper door sealing.